- ACC202 Assessment 2: Business Report, Individual Assignment, CIBT, UK

- HI5017: Identify the various types of management accounting information, specifically, 4 financial and 4 non-financial: Managerial Accounting, Group Assignment, HID, UK

- HI5017: Group Assignment: Managerial Accounting, HID, UK

- ECE2110: In this assignment you will create eight 8 1⁄2” X 11” physical poster or digital infographic: Learning Through Play, Assignment, CDI College, UK

- MKT264: Please read the following case study about Jasmi’s Corporation W.L.L., a Bahraini company: Group Case Study Analysis, Assignment, UK

- LD9706: Marketing Metrics and Analysis, Assignment, NUN, UK

- BDV6223: Structuring System Process Requirements: Business Applications Development, Group Assignment, MMU, UK

- BDV6223:Determining Systems Requirements: Business Applications Development, Group Assignment, MMU, UK

- BDV6223: Planning and Managing the Information System Project: Business Applications Development, Group Assignment, MMU, UK

- BDV6223: Foundations for Systems Development: Business Applications Development, Group Assignment, MMU, UK

- BDV6223: Business Applications Development, Group Assignment, MMU, UK

- 5CO01:Evaluate the advantages and disadvantages of the organisation structure in your organisation :Organizational Performance and Culture in Practice, Assignment, CIPD, UK

- Why learning and development activities are of benefit to individuals and organisations: CIPD Level 3, 3CO04 Essentials of people practice, Assignment, UK

- Explain the purpose and components of performance management: CIPD Level 3, 3CO04 Essentials of people practice, Assignment, UK

- CIPD Level 3: Develop selection criteria and shortlist candidate applications for interview for an identified role: 3CO04 Essentials of people practice, Assignment, UK

- CIPD Level 3, 3CO04 Essentials of people practice: Explain different ways in which you can prepare information for specified roles, Assignment, UK

- Analyse the features, principles and values of outcomes based practice: NVQ Level 5 NVQ Level 5 Diploma In Leadership & Management for Adult Care Unit 7: Outcomes based person centred practice in Adult Care, Assignment , UK

- Analyse the structure of the organization relative to health and safety: UNIT 2 Develop and implement the health and safety policy, Assignment, PQ, UK

- Explain How To Achieve Positive Interactions Within An Adult Care Setting/service Considering: Level 5 Diploma in Leadership and Management for Adults Care Assignment, DC, UK

- Unit 6: Website Development Pearson BTEC Level 3 National Extended Certificate in Information Technology Assignment, UK

Alarm Company Ltd manufactures alarm control panels. It has analyzed the fixed and variable costs relating to a panel: Business Operations in Engineering Assignment, UOB, UK

| University | University of Bath (UOB) |

| Subject | Business Operations in Engineering |

Learning Outcomes

- Explain the functions carried out by different engineering companies in the sectors in which they operate.

- Explain the organizational types of the three given engineering companies.

- Outline how information flows through an engineering company in relation to an engineering activity.

- Discuss how improvements in information flow could enhance the functional activities of an engineering company.

- Evaluate the information flow through an engineering company in relation to an engineering activity.

Task 1

Alarm Company Ltd manufactures alarm control panels. It has analyzed the fixed and variable costs relating to a panel supplied on a subcontract basis to companies that install fire alarm systems. The Fire Alarm Panel has the following data:

Overheads: £18,000

Fixed cost tooling: £2,000

Variable cost per unit: £18

The director of manufacturing requires you to produce an analysis for production volumes in the range of 100 to 1400 per month.

- Based on a selling price of £40, construct a break-even chart and use this to find the break-even volume.

- Investigate the effect of increasing the selling price to £45.

- It is decided to fix the production level at 1000 units a month with each unit selling for £45. A few weeks later Alarm Company Ltd receives an inquiry from a new customer. This is a DIY store and it wants to place a trial order of 500 units but at the nonnegotiable price of £35 per unit. Should the company accept the order given that the average cost per unit based on a 1000-unit monthly run is £38?

Task 2

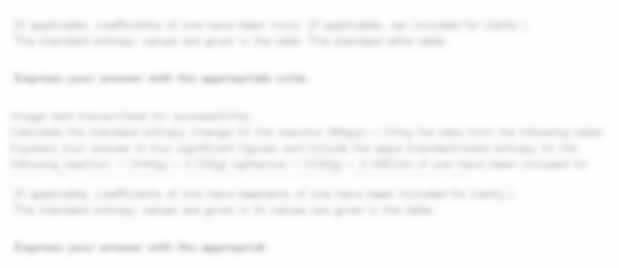

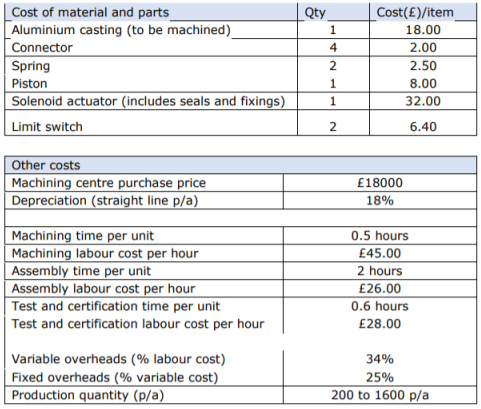

A subcontractor produces fuel control valves for the aerospace industry. The tables below contain information about the cost of producing a particular valve.

The body of the valve is the only part that is machined. This is produced from a bought-in casting. The machining center currently in use is old and has stopped working and the manufacturing director is keen to replace it with a new one.

The finance director is not convinced that the machine should be replaced given the variable quantities of valves likely to be produced each year, particularly as the casting supplier has recently set up its own specialized machine shop. The supplier has tendered to supply the valve body fully finished at a guaranteed fixed price of £80 a unit.

Given that valve sales over the next 12 months may not be more than 600 what would be your recommendation:

- purchase the machining center and machine the body?

- buy in the body ready finished?

- Present a full costing analysis for the valve initially working on a figure of 1000 units per annum using a spreadsheet. Then carry out a ‘what if’ evaluation using production levels in the range of 200 to 1600 units p/a.

Buy Answer of This Assessment & Raise Your Grades

Studentsassignmenthelp.co.uk offers academic writing services for students of all academic levels, from undergraduate to graduate and beyond. Our team of talented assignment writers is highly-educated professionals that specialize in a variety of academic subjects and topics, ensuring that you get the exact help you need, whatever your academic needs may be.