- OTHM Level 5 Unit H/650/1142 Professional Supervision Assignment: Health & Social Care Case for Managing Supervision and Performance

- ATHE Level 4 Unit 15 Software Testing Frameworks Assignment: TDD and BDD Strategy for Medical Data Validation Script in Python

- ATHE Level 4 Unit 12 Web Design and Programming Assignment: CTO Birdwatching App Development for Urban Wildlife Insights

- ATHE Level 4 Unit 21 Synoptic Computing Project Assignment: Smart Parking App Design for Urban Mobility Solution

- ATHE Level 4 Unit 1 IT Systems Development Assignment: The World of Art Case Study for Global Online Sales Expansion

- CYP6032 Leading Multi-Agency Health & Social Care Assignment: Vulnerable Groups Literature Review and Reflective Evaluation

- Unit 21 – L/618/8101 Geotechnical Design Assignment 1: Scunthorpe Station Overpass & Bridge Infrastructure Proposal

- Y/616/7445 Unit 039 Diabetes Awareness Assignment: Understanding, Managing and Supporting Individuals with Diabetes

- DHCS 12 (M/650/5189) Understand Mental Ill Health Assignment: Explore DSM/ICD Disorders, Discrimination & Capacity

- Unit 8 Social Media Strategy Assignment 2: Planning, Execution & Evaluation for Organisational Growth

- CIPD Level 7CO01 Strategic People Management Assignment: Demographic Trends, Legal Reforms, Innovation & Resilience in the Workplace

- Financial Accounting Assignment: Lee’s Sole Trader Transactions & Cash Flow Analysis

- L/508/4603 NCFE Level 3 Sport and Exercise Massage Assignment 3: Consultation & Technique Review for Two Contrasting Athletes

- F/650/1141 Unit 4 Team Management and Recruitment Assignment: Health & Social Care Case Study for Effective Leadership and PDPA-Compliant Hiring

- R/650/1138 OTHM Level 5 Assignment: Working in Partnership in Health and Social Care

- NVQ Level 3 Health and Safety Risk Management Assignment: Practical Assessment and Workplace Application

- MBA7068 Strategic Portfolio Assignment 1: Global Business Trends and Managerial Skill Development

- Mechanical Services Innovation: Hotel Rotation Case Study for Energy-Efficient Heat Pump Integration

- K/618/4170 ATHE Level 3 Unit 4 Assignment: Working in Health and Social Care

- T/618/4169 ATHE Level 3 Unit 3 Assignment: Human Growth and Development in Health and Social Care

PROD1002: A company manufactures components with a critical dimension required to be in the range of 115mm to 116mm: Quality Engineering Assignment, UOG, UK

| University | University of Greenwich (UOG) |

| Subject | PROD1002: Quality Engineering |

A company manufactures components with a critical dimension required to be in the range of 115mm to 116mm.

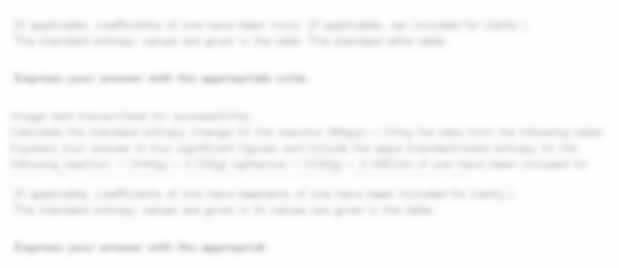

The gauge used to measure this dimension has recently returned from calibration. In order to test whether it is capable of being used to measure this critical dimension, a Gage Repeatability and Reproducibility (R&R) study is to be carried out. The measurements of 10 sample components, each measured twice by two different operators are given below:

Use this data, along with the Gauge R&R calculator to demonstrate that this measurement system is capable of assessing the components for the required dimension.

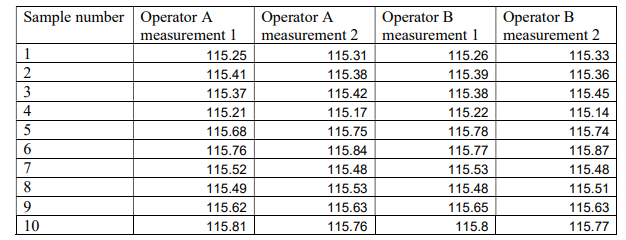

Historically, these components have been machined in batches of 5 on a Honzaki CNC vertical milling machine. The measurements of the last 20 batches made on this machine are given in the table below:

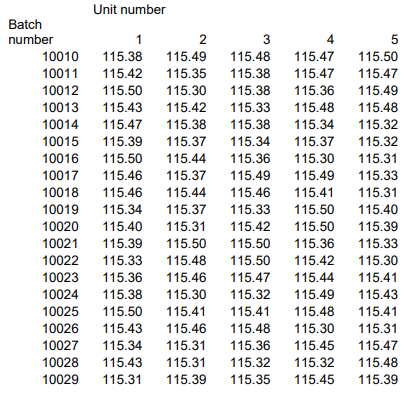

The company has recently bought a new Kawada CNC vertical milling machine to replace the Honzaki machine. The first 10 batches of components produced on the Kawda machine are measured and the results are given in the table below:

Calculate the Cp and Cpk process capability indices for both processes (you may assume that the data are normally distributed) and comment on which, if either, the process appears to be the better suited to this task. State what improvements to the process you might recommend, and who you would expect to be responsible for such actions.

Use an appropriate Statistical Process Control chart to assess whether there is any difference in the components produced by the two machines. (hint: calculate the x-bar and r chart control limits, plot the charts, and investigate for any “out of control” conditions)

Buy Answer of This Assessment & Raise Your Grades