- Wind tunnel testing plays an important role in the design of aircraft. It provides a check on the accuracy of the initial design: Aerospace Engineering, Coursework, UOL, UK

- Select and apply appropriate computational and analytical techniques to model complex problems, recognising the limitations of the techniques employed :AHEP- Assignment 1 , UK

- Cipd level 5 5HR01 Assignment 3 June 2024 : Employment relationship management, UK

- Pearson BTEC Level 3 Unit 6: Website Development : Website evaluation, Assignment, UK

- BTEC Unit 20: Explain, analyze, optimize, and enhance the operation of a simple combinational logic circuit with three (03) fail-safe sensors and one (01) emergency shutdown switch- Digital Principles Assignment 1, UK

- Complete a report to compare three academic sources to identify levels of relevance and application: Health wellbeing and social care, Assignment, UK

- Fluid Power Diagrams – Applications Of Pneumatics And Hydraulics, Tutor Marked Assignment 2, TU, UK

- Fluid Power Diagrams – Applications Of Pneumatics And Hydraulics, Tutor Marked Assignment 1, TU, UK

- Pearson BTEC Level 3 Unit 8 Mechanical Principles of Engineering Systems : Statics, Assignment, UK

- CBB508 – Understand the structure of the eukaryotic cell and the functions of the different components: Cells Assignment, OCN, UK

- Unit4003: Engineering Science I : Examine scientific data using both quantitative and qualitative methods, Assignment, HNC, UK

- COM4007 – Identify design, usability and accessibility issues involved in delivering websites: Introduction to Web Authoring Assignment, AU, UK

- Access to HE Diploma Assessment Materials Sourcing and Reading Information (2024-25) : Computing, Assignment, OCN, UK

- Level 5 This unit will develop your knowledge of the importance of leadership and management theories and styles: The Principles of Leadership and Management in Adult Social Care, Assignment, UK

- Unit 4 – Identify indicators of your wellbeing and wellbeing deterioration: Promoting Personal Wellbeing, Assignment, UK

- Level 6 NUR6065 : An exploration of the care and management of a patient with complex health needs- Nursing care: adult, Assignment, BCU, UK

- COM4008: Demonstrate a knowledge and understanding of databases and data management systems- Introduction to Databases, Assignment , AU, UK

- 3CO04 Level 3 CIPD Assignment : June 2024 – Essentials of people practice

- 3CO02 Level 3 CIPD Assignment : June 2024 – Principles of analytics

- 5013FTE Internal Combustion Engine Simulation Report: Vehicle Systems and Development, Assignment, CU, UK

Component Function and Operating Environment: Manufacturing Assignment, UK

| Subject | Manufacturing Assignment |

TASK:

Students are expected to produce a report that would address the questions listed in Table 1. It is worth to note that one/two sections may be linked to each other; therefore, read the sections carefully before attempting to write the report.

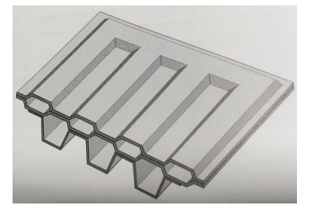

You are given the following material choices: aluminium alloys, copper alloys, cast iron, different grades of steel, nickel-based alloys and composite material. You are asked to choose a material from this list for the main part of a domestic radiator to be made later this year or early next year. This can be used during winter to warm up houses in the UK. Figure 1 shows a section through a typical domestic radiator that is used in basic water central heating. It shows that the section is made of sheets manufactured/joined in lap joint configuration.

Buy Answer of This Assessment & Raise Your Grades

This component is the part relating to section 1, 2 and 4 of the questions listed in Table 1. Given that a radiator is a type of heat exchanger, when addressing section 1 and 2 use the requirement for a heat exchanger to narrow down the materials choices. Scientific reasons for the selected material(s) should be included.

Format of the Report: About a 1500-word report is expected as the deliverable, with a minimum font size 10. Line spacing should be no more than 1.5 lines. This word limit excludes figures, tables, graphs, list of references and appendices. Ensure that you provide a list of the academic references at the end of the work; use University APA referencing system for in-text citation and the listing of the references. Text should be written for academic audience; hence, ensure you use the relevant rules (e.g., use of third person, passive format and include references within the text). Appendices should be used for diagrams and information if necessary. The report can be submitted in Pdf or Doc format.

Do You Need Assignment of This Question

- Component Function and Operating Environment

Outline the service conditions that are caused by the component’s function {i.e. the heat exchanger) and the environment in which it functions and the conditions/ stresses the component will be designed to withstand (e.g.. types of stresses, temperatures, service atmospheres etc.). Where possible provide some quantification. List materials properties linked to the requirements. - Material Properties and Selection.

You are asked to select the most appropriate material for the component (the main part of a domestic radiator), list the best material(s) if minimising cost is the objective. Provide the reason for your selection.You will plot one or two graph(s) in Granta Edupack {or using data from a reference book} to justify your choice. Make sure the correct attributes/ properties are used during material setection.

2b You have now been informed that the heat exchanger is going to be used in the production line in chemical industry with a corrosive fluid funning through it. Identify the best material(s) that suits this new application. Provide the reason for your selection.

Are You Looking for Answer of This Assignment or Essay

Excel in Manufacturing with our expertise in Manufacturing Assignment. As your academic support, we provide comprehensive assistance through specialized assignment help services and meticulous report writing service in the UK. UK students, optimize your academic journey by investing in our experts’ personalized assistance. Our commitment ensures success in mastering manufacturing concepts. Click to access our top-notch support and conquer your assignments with confidence!