- OTHM Level 5 Unit H/650/1142 Professional Supervision Assignment: Health & Social Care Case for Managing Supervision and Performance

- ATHE Level 4 Unit 15 Software Testing Frameworks Assignment: TDD and BDD Strategy for Medical Data Validation Script in Python

- ATHE Level 4 Unit 12 Web Design and Programming Assignment: CTO Birdwatching App Development for Urban Wildlife Insights

- ATHE Level 4 Unit 21 Synoptic Computing Project Assignment: Smart Parking App Design for Urban Mobility Solution

- ATHE Level 4 Unit 1 IT Systems Development Assignment: The World of Art Case Study for Global Online Sales Expansion

- CYP6032 Leading Multi-Agency Health & Social Care Assignment: Vulnerable Groups Literature Review and Reflective Evaluation

- Unit 21 – L/618/8101 Geotechnical Design Assignment 1: Scunthorpe Station Overpass & Bridge Infrastructure Proposal

- Y/616/7445 Unit 039 Diabetes Awareness Assignment: Understanding, Managing and Supporting Individuals with Diabetes

- DHCS 12 (M/650/5189) Understand Mental Ill Health Assignment: Explore DSM/ICD Disorders, Discrimination & Capacity

- Unit 8 Social Media Strategy Assignment 2: Planning, Execution & Evaluation for Organisational Growth

- CIPD Level 7CO01 Strategic People Management Assignment: Demographic Trends, Legal Reforms, Innovation & Resilience in the Workplace

- Financial Accounting Assignment: Lee’s Sole Trader Transactions & Cash Flow Analysis

- L/508/4603 NCFE Level 3 Sport and Exercise Massage Assignment 3: Consultation & Technique Review for Two Contrasting Athletes

- F/650/1141 Unit 4 Team Management and Recruitment Assignment: Health & Social Care Case Study for Effective Leadership and PDPA-Compliant Hiring

- R/650/1138 OTHM Level 5 Assignment: Working in Partnership in Health and Social Care

- NVQ Level 3 Health and Safety Risk Management Assignment: Practical Assessment and Workplace Application

- MBA7068 Strategic Portfolio Assignment 1: Global Business Trends and Managerial Skill Development

- Mechanical Services Innovation: Hotel Rotation Case Study for Energy-Efficient Heat Pump Integration

- K/618/4170 ATHE Level 3 Unit 4 Assignment: Working in Health and Social Care

- T/618/4169 ATHE Level 3 Unit 3 Assignment: Human Growth and Development in Health and Social Care

A lab scale 2L bioreactor operates at a volumetric productivity of 4 g L-1 h1 and is integrated with a cylindrical 400 mL separator: Chemical Engineering, Assignment, UCL, UK

| University | University College London (UCL) |

| Subject | Chemical Engineering |

Questions

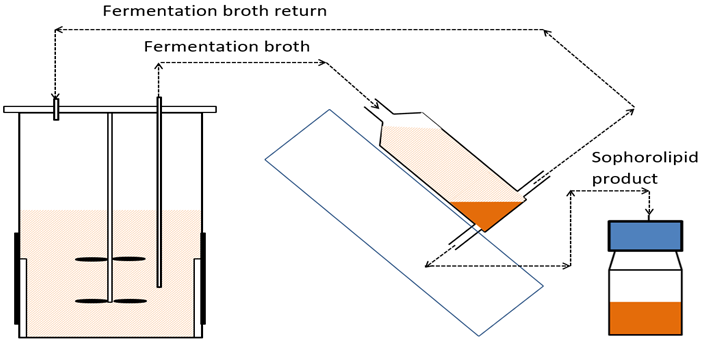

1. A lab scale 2L bioreactor operates at a volumetric productivity of 4 g L-1 h1 and is integrated with a cylindrical 400 mL separator (Figure 1) with an L/D ratio = 4. The residence time in the separator is 16 min. The system described is characterised by Re = 105. The fermentation broth is characterised by μa = 0.25 Pa.s, p = 1050 kg m23.

Do You Need Assignment of This Question

a) Calculate the current length and diameter of the separator in operation.

b) If residence time is reduced to 8min will there be an interference on settling?

2. Propose an approach for scaling up the lab scale separator described above for a bioreactor volume of 10 m3, operating at the same volumetric productivity and a maximum residence time of 16 min (see Figure 1).

- Discuss your considerations for the basis of performing the scale up design.

- State any relevant parameters for design and / or verification.

- Detail any further measurements which would be needed to support the scale up design.

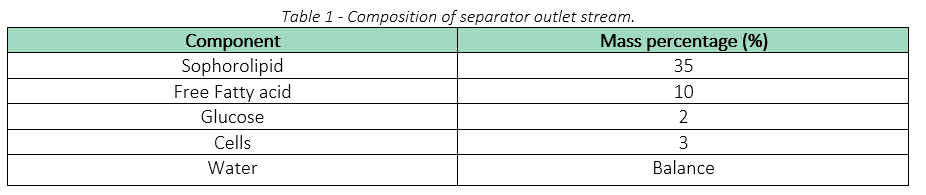

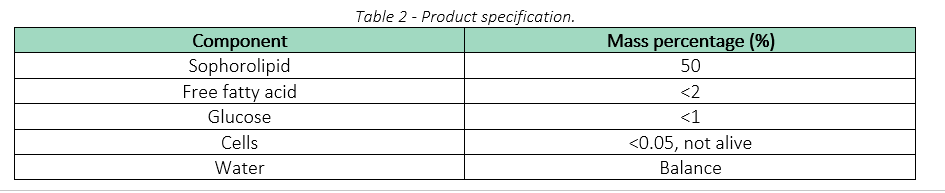

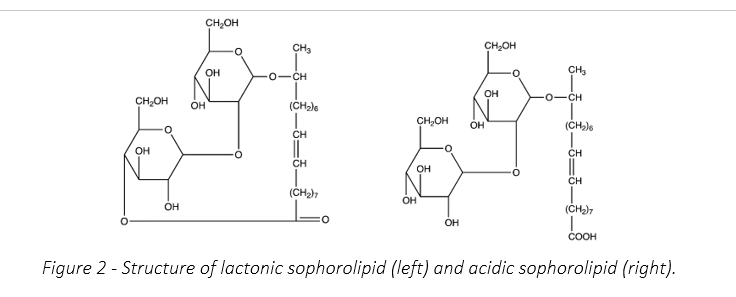

3. Propose a downstream procedure to ensure that the final product, taken from the separator and having the composition shown in Table 1, meets the specifications given in Table 2 so it is suitable to sale to customers. Aim to provide a process that can be applied industrially for as low a price as possible. State any assumptions and trade-offs/compromises in the design.

Buy Answer of This Assessment & Raise Your Grades

Are You Looking for Answer of This Assignment or Essay

Are you struggling with your Chemical Engineering assignment? Our Assignment Help Company in the UK is here to make things easier for you. If you need someone to do your assignment for you, or engineering assignment writing help online, we’ve got you covered. UK students can pay our expert to get the professional support they need to excel in their courses.