- BA1540 International Business and Accounting Assessment 1 Brief 2026 | UOL

- LNDN09006 Marketing Communication Assessment Brief 2026 | UWS

- ENI08106 Marketing and Market Research in Practice Assessment 2 Brief 2026

- 6ECON004W Development Economics Assessment Brief 2026 | UOW

- Qualifi Level 6 BA604 Business Law Assessment Brief 2026 | University of East London

- ENI08106 Marketing and Market Research in Practice Assessment Brief 2026 | ENU

- COM5024 Advanced Databases Assessment Brief 2026 | Arden University

- HWSC3001 Academic Writing Skills for Success 1 Assessment Brief 2026 | OBU

- FDY3007 Planning for Your Future Success Assessment Brief 2026 | Arden University

- 400IT Networking Coursework 1 Practical Assessment – Lab Scenario Worksheet

- MAR001-1 Principles of Marketing Assignment Brief 2026 | University of Bedfordshire

- MAR0022-1 Consumer Behaviour Assignment 1 Brief 2026 | University of Bedfordshire

- BTM4FUB Fundamentals of Business Finance Assignment 2 Brief 2026 | CCCU

- OTHM Level 6 Diploma In Health And Social Care Management Assignment Brief 2026

- PBS7000J Capstone Project Final Assessment 2026 | University of Plymouth

- ILM Unit (8600–308) Understanding leadership Assignment Brief 2026

- PSY771 Research Project Assignment Brief 2026 | Wrexham University

- CIH Level 3 H3007 Involving Housing Service Users Assignment Brief 2026

- BTEC Level 3 Unit 11 Psychological Perspectives Assignment Brief 2026

- HSC 4001 Epidemiology and Health Science Assessment Brief 2026 | BNU

A lab scale 2L bioreactor operates at a volumetric productivity of 4 g L-1 h1 and is integrated with a cylindrical 400 mL separator: Chemical Engineering, Assignment, UCL, UK

| University | University College London (UCL) |

| Subject | Chemical Engineering |

Questions

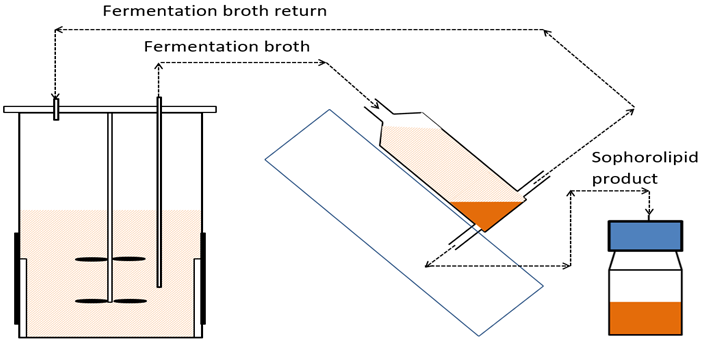

1. A lab scale 2L bioreactor operates at a volumetric productivity of 4 g L-1 h1 and is integrated with a cylindrical 400 mL separator (Figure 1) with an L/D ratio = 4. The residence time in the separator is 16 min. The system described is characterised by Re = 105. The fermentation broth is characterised by μa = 0.25 Pa.s, p = 1050 kg m23.

Do You Need Assignment of This Question

a) Calculate the current length and diameter of the separator in operation.

b) If residence time is reduced to 8min will there be an interference on settling?

2. Propose an approach for scaling up the lab scale separator described above for a bioreactor volume of 10 m3, operating at the same volumetric productivity and a maximum residence time of 16 min (see Figure 1).

- Discuss your considerations for the basis of performing the scale up design.

- State any relevant parameters for design and / or verification.

- Detail any further measurements which would be needed to support the scale up design.

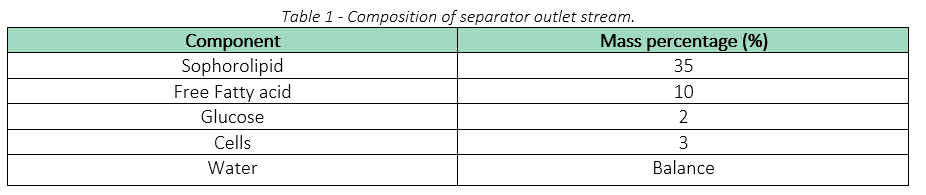

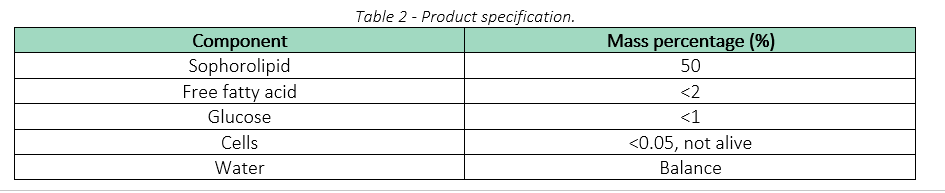

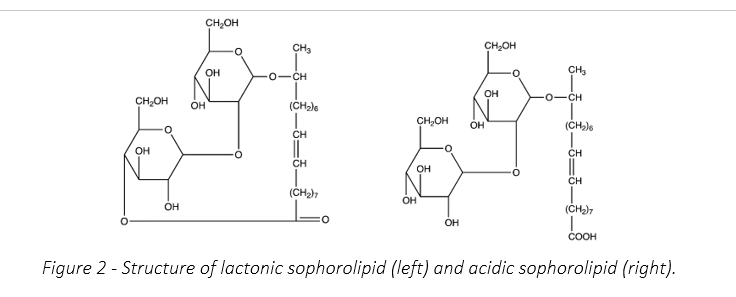

3. Propose a downstream procedure to ensure that the final product, taken from the separator and having the composition shown in Table 1, meets the specifications given in Table 2 so it is suitable to sale to customers. Aim to provide a process that can be applied industrially for as low a price as possible. State any assumptions and trade-offs/compromises in the design.

Buy Answer of This Assessment & Raise Your Grades

Are You Looking for Answer of This Assignment or Essay

Are you struggling with your Chemical Engineering assignment? Our Assignment Help Company in the UK is here to make things easier for you. If you need someone to do your assignment for you, or engineering assignment writing help online, we’ve got you covered. UK students can pay our expert to get the professional support they need to excel in their courses.