- Qualifi Level 6 BA604 Business Law Assessment Brief 2026 | University of East London

- ENI08106 Marketing and Market Research in Practice Assessment Brief 2026 | ENU

- COM5024 Advanced Databases Assessment Brief 2026 | Arden University

- HWSC3001 Academic Writing Skills for Success 1 Assessment Brief 2026 | OBU

- FDY3007 Planning for Your Future Success Assessment Brief 2026 | Arden University

- 400IT Networking Coursework 1 Practical Assessment – Lab Scenario Worksheet

- MAR001-1 Principles of Marketing Assignment Brief 2026 | University of Bedfordshire

- MAR0022-1 Consumer Behaviour Assignment 1 Brief 2026 | University of Bedfordshire

- BTM4FUB Fundamentals of Business Finance Assignment 2 Brief 2026 | CCCU

- OTHM Level 6 Diploma In Health And Social Care Management Assignment Brief 2026

- PBS7000J Capstone Project Final Assessment 2026 | University of Plymouth

- ILM Unit (8600–308) Understanding leadership Assignment Brief 2026

- PSY771 Research Project Assignment Brief 2026 | Wrexham University

- CIH Level 3 H3007 Involving Housing Service Users Assignment Brief 2026

- BTEC Level 3 Unit 11 Psychological Perspectives Assignment Brief 2026

- HSC 4001 Epidemiology and Health Science Assessment Brief 2026 | BNU

- CSE4202 Fundamentals in Programming Assessment Brief 2026 | CMU

- BS7014 International Business Strategy Assignment Brief 2026 | KU London

- BUS4014 People Management Assignment Plans and Structures- Plan 2026 | Arden University

- BUS4013 Technology and Innovation Assignment Plans and Structures- Plan 2026 | Arden University

PROD1002: A company manufactures components with a critical dimension required to be in the range of 115mm to 116mm: Quality Engineering Assignment, UOG, UK

| University | University of Greenwich (UOG) |

| Subject | PROD1002: Quality Engineering |

A company manufactures components with a critical dimension required to be in the range of 115mm to 116mm.

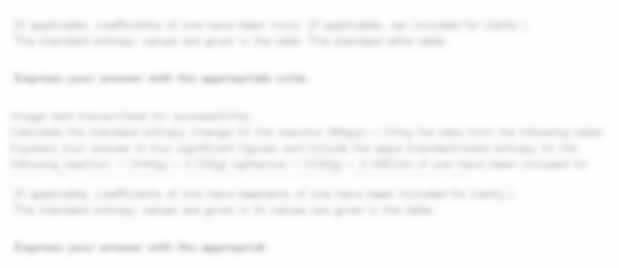

The gauge used to measure this dimension has recently returned from calibration. In order to test whether it is capable of being used to measure this critical dimension, a Gage Repeatability and Reproducibility (R&R) study is to be carried out. The measurements of 10 sample components, each measured twice by two different operators are given below:

Use this data, along with the Gauge R&R calculator to demonstrate that this measurement system is capable of assessing the components for the required dimension.

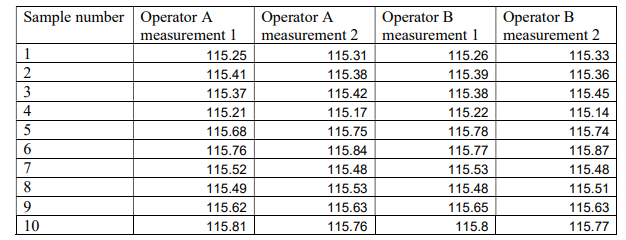

Historically, these components have been machined in batches of 5 on a Honzaki CNC vertical milling machine. The measurements of the last 20 batches made on this machine are given in the table below:

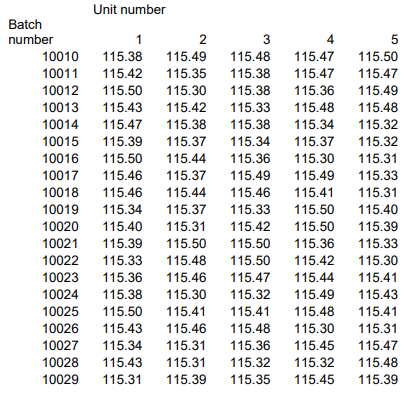

The company has recently bought a new Kawada CNC vertical milling machine to replace the Honzaki machine. The first 10 batches of components produced on the Kawda machine are measured and the results are given in the table below:

Calculate the Cp and Cpk process capability indices for both processes (you may assume that the data are normally distributed) and comment on which, if either, the process appears to be the better suited to this task. State what improvements to the process you might recommend, and who you would expect to be responsible for such actions.

Use an appropriate Statistical Process Control chart to assess whether there is any difference in the components produced by the two machines. (hint: calculate the x-bar and r chart control limits, plot the charts, and investigate for any “out of control” conditions)

Buy Answer of This Assessment & Raise Your Grades