- 6BM040 Honours Research Project Assessment Brief 2026 | University of Wolverhampton

- A334 English Literature from Shakespeare to Austen Tutor-Marked Assignment 03, 2026 | OU

- ADV767 Advanced Clinical Reasoning in Musculoskeletal Conditions Assessment Brief 2026 | UOP

- IS2184 Information Systems Management Individual Assignment 2026 | UOL

- MK7050 Principles and Practices of International Business Assessment Brief 2026

- BA1540 International Business and Accounting Assessment 1 Brief 2026 | UOL

- LNDN09006 Marketing Communication Assessment Brief 2026 | UWS

- ENI08106 Marketing and Market Research in Practice Assessment 2 Brief 2026

- 6ECON004W Development Economics Assessment Brief 2026 | UOW

- Qualifi Level 6 BA604 Business Law Assessment Brief 2026 | University of East London

- ENI08106 Marketing and Market Research in Practice Assessment Brief 2026 | ENU

- COM5024 Advanced Databases Assessment Brief 2026 | Arden University

- HWSC3001 Academic Writing Skills for Success 1 Assessment Brief 2026 | OBU

- FDY3007 Planning for Your Future Success Assessment Brief 2026 | Arden University

- 400IT Networking Coursework 1 Practical Assessment – Lab Scenario Worksheet

- MAR001-1 Principles of Marketing Assignment Brief 2026 | University of Bedfordshire

- MAR0022-1 Consumer Behaviour Assignment 1 Brief 2026 | University of Bedfordshire

- BTM4FUB Fundamentals of Business Finance Assignment 2 Brief 2026 | CCCU

- OTHM Level 6 Diploma In Health And Social Care Management Assignment Brief 2026

- PBS7000J Capstone Project Final Assessment 2026 | University of Plymouth

Unit 5048 J/650/2990 Sensors and Automation BTEC Level 5

| Subject | Unit 5048: Sensors and Automation |

Introduction

Modern developments and applications of automation in industry rely on complex and highly reliable industrial communication networks. Industrial communication is typically a mixture of multilayered, multidimensional networks involving fieldbuses, software packages, media, and a host of other tools. To be able to install, commission, maintain and troubleshoot an industrial plant, a competent engineer requires a good understanding of sensor and actuator technologies and core communication technologies. This unit equips students with the requisite knowledge of sensors and actuators and the key skills underpinning popular industrial communication networks, such as PROFINET, Ethernet IP, Modbus, IO Link and EtherCAT, thereby extending the breadth of employment to which students pursuing a career in network technologies can aspire.

Thus, this unit aims to provide students with the skills and competencies required to work in the areas of industrial computer control, automation, and Industry 4.0. Fundamental concepts underpinning the use of sensors and industrial communication networks for automation are introduced, and students are given the essential knowledge and skills required for the use of Ethernet-based technology in support of real-time industrial network environments. An appreciation of technologies using wire pairs, fibre optics, satellites and microwave transmission will be provided.

The unit will provide specialist knowledge for work with industrial controllers (e.g. programmable logic controllers (PLCs)) in the areas of manufacturing and automation using popular network technologies such as PROFINET, together with an appreciation of security aspects in relation to network- and cloud-based solutions.

On successful completion of this unit, students will have gained knowledge and skills in the application of PLCs to industrial control, and the design, development and evaluation of Ethernet-based communication and automation systems. Through appropriate tasks and assignments, students will be exposed to good engineering practices in software engineering, and in the installation, testing and maintenance of networked automation systems.

Learning Outcomes

By the end of this unit, students will be able to:

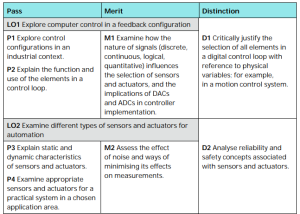

LO1 Explore computer control in a feedback configuration

LO2 Examine different types of sensors and actuators for automation

LO3 Demonstrate design and implementation skills in programming PLC-based devices

LO4 Investigate the PROFINET standard and PROFINET operations and data analysis techniques.

Do You Need Assignment of This Question

Essential Content

LO1 Explore computer control in a feedback configuration

Types of control systems:

- Industrial control systems

- Continuous-time and discrete control

- Types of controllers – continuous, discrete and logical

- Applications of different types control systems in chosen occupation/sector (e.g., space, aeronautical, mechanical, manufacturing etc.).

Control configurations:

- Open-loop systems

- Closed-loop systems

- Feedback, feedforward and cascade loops.

Control-loop elements:

- Essential components in a control loop

- Sensors and actuators – definition and examples

- Data acquisition, roles of analogue-to-digital converter (ADC) and digital-to-analogue converter (DAC).

LO2 Examine different types of sensors and actuators for automation

Overview of measurement concepts:

- Physical process variables: static and dynamic characteristics

- Signals and noise in measurements.

Sensors for automation:

- Measurement of physical quantities: typical sensors to measure temperature, pressure, flow, speed, position, and so on

- Concepts of range, calibration, precision, reliability, limitations and appropriate use, and so on.

Actuators for automation:

- Common actuators, characteristics and uses – valves, servomotors, and so on; control and safety concepts.

LO3 Demonstrate design and implementation skills in programming PLC-based devices

Programmable logic controllers (PLCs):

- Architecture, operation, scan cycle, inputs and outputs

- CPU, input and output modules, addressing convention

- Examples of industrial application (e.g. satellite and microwave transmission, avionics systems for remote sensing, geophysical multisensor system, microsensors, electronic and optical actuation, bespoke PLC network products).

Programming for PLCs:

- Programming using IEC 61131-3 standard languages such as ladder diagrams, function block diagrams, continuous function charts, structured text and sequential function charts

- Project configuration, program organisation units (POUs), tasks

- Application development using software environments; for example, human–machine interface (HMI) design using CODESYS and Siemens S7 PLCs

- Network automation applications and related tools and platforms.

Skills and competencies:

- Industrial computer control, automation, Industry 4.0 and beyond

- Integration of automation and digital systems, and impact on organisations.

LO4 Investigate the PROFINET standard and PROFINET operations and data analysis techniques.

Industrial communication networks:

- PROFINET, Ethernet IP, Modbus, IO Link, EtherCAT and other equivalent options

- Overview of operation and maintenance: types of network maintenance, monitoring and diagnostics; evaluation and implementation of maintenance procedures; troubleshooting methodologies, tools and techniques for networks and IT infrastructure; workforce roles such as engineering technician, network engineer, systems engineer, and relevant competencies; occupational standards to meet sector demands).

Buy Answer of This Assessment & Raise Your Grades

Overview of PROFINET systems:

- Requirements of real-time control networks

- Network topologies (e.g., bus, ring, start, tree, mesh, and hybrid) used in PROFINET networks

- The PROFINET standard

- Application areas for PROFINET networks (including organisational context, PROFINET Network Engineer roles and occupational relevance, CPD).

Design and implementation of PROFINET systems:

- PROFINET system design, protocols and principles of operation

- PROFINET installation, troubleshooting (e.g., isolate, repair and escalate faults based on data) and maintenance in the context of Industry 4.0

- Use of appropriate software and hardware tools; for example, ProfiTrace, Wireshark

- Use of cloud-based systems for maintenance and analytics.

Learning Outcomes and Assessment Criteria

Recommended Resources

Note: See HN Global for guidance on additional resources.

Print Resources

- Groover, M.P. (2020) Automation, Production Systems, and Computer-Integrated Manufacturing. 5th Ed. Addison Wesley.

- Love, J. (2007) Process Automation Handbook: A Guide to Theory and Practice. Springer-Verlag.

- Popp, M. (2015) Industrial communication with PROFINET. PROFIBUS Nutzerorganisation e.V. (PNO).

- Powell, J. and Vandelinde, H. (2015) Catching the Process Fieldbus: An introduction to PROFIBUS and PROFINET. 2nd Ed. Siemens Milltronics Process Instruments.

Websites

- http://www.profibus.com PROFIBUS & PROFINET International (PI) (General reference)

- http://www.profibusgroup.com PROFIBUS.PROFINET United Kingdom ‘All about PROFIBUS, PROFINET, IO-Link and omlox in the UK’ (General reference)

- http://www.profinews.com PROFINEWS ‘PROFINET, PROFIBUS, IO-Link, and omlox news from around the world’ (General reference)

- http://www.automation.com Automation.com ‘A subsidiary of the International Society of Automation’ (General reference)

- http://www.controleng.com Control Engineering ‘Control Engineering Magazine’ (General reference)

- http://www.controlglobal.com Control (General reference)

Are You Looking for Answer of This Assignment or Essay

Journals

Note: Example journals listed below provide a broad range of articles related to unit content and those relevant for the qualification. Staff and students are encouraged to explore these journals and any other suitable journals to support the development of academic study skills, and subject specific knowledge and skills as part of unit level delivery.

Control Engineering Practice. ISSN: 0967-0661.

IET Control Theory and Applications. ISSN: 1751-8644.

If you are facing difficulty in BTEC Level 5 Unit 5048 Sensors and Automation asignment, then you have come to the right place. Our experts provide a specially designed assignment help service for students. We are here to provide a free answer list written by experts for students, which you can read to increase your study efficiency. Hurry up and get your BTEC assignment done with high quality and AI free before the deadline.